One day in math class, Raphael Palefsky-Smith was browsing the Internet when he came upon an article on 3D printers. Intrigued, he set out to buy one. Two days later the 17-year-old had raised over $700 from 14 students and a faculty member. With that money, he purchased a Solidoodle 2 for his school in Santa Cruz, California.

This sort of wild excitement is common in the $2.5 billion industry, which has grown 29 percent since 2012. Now, companies are turning to lower education as the next frontier. In the past six months, two of the 3D printing industry’s biggest companies launched education initiatives. One of them is MakerBot, which has provided over 400,000 students access to a 3D printer.

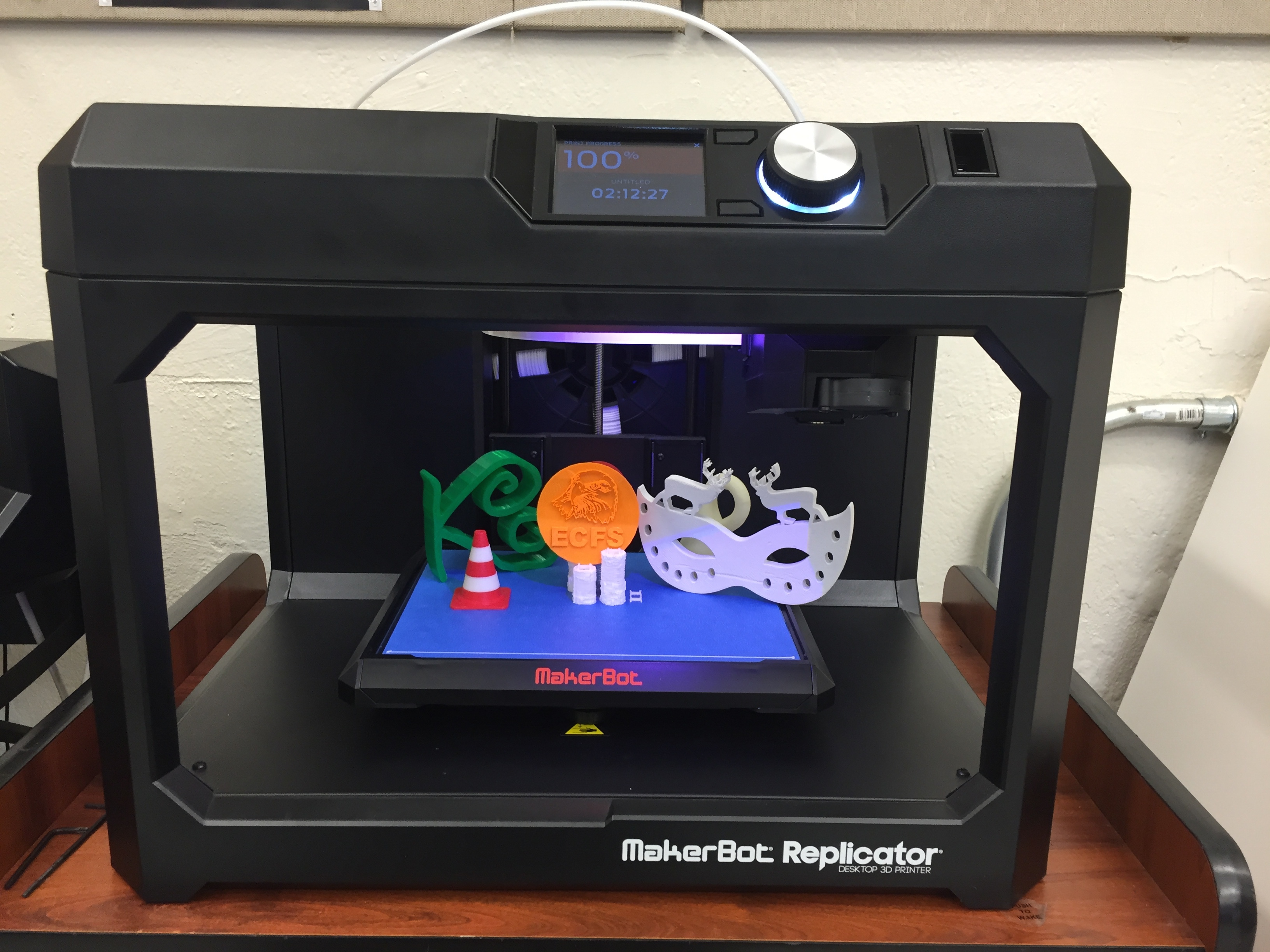

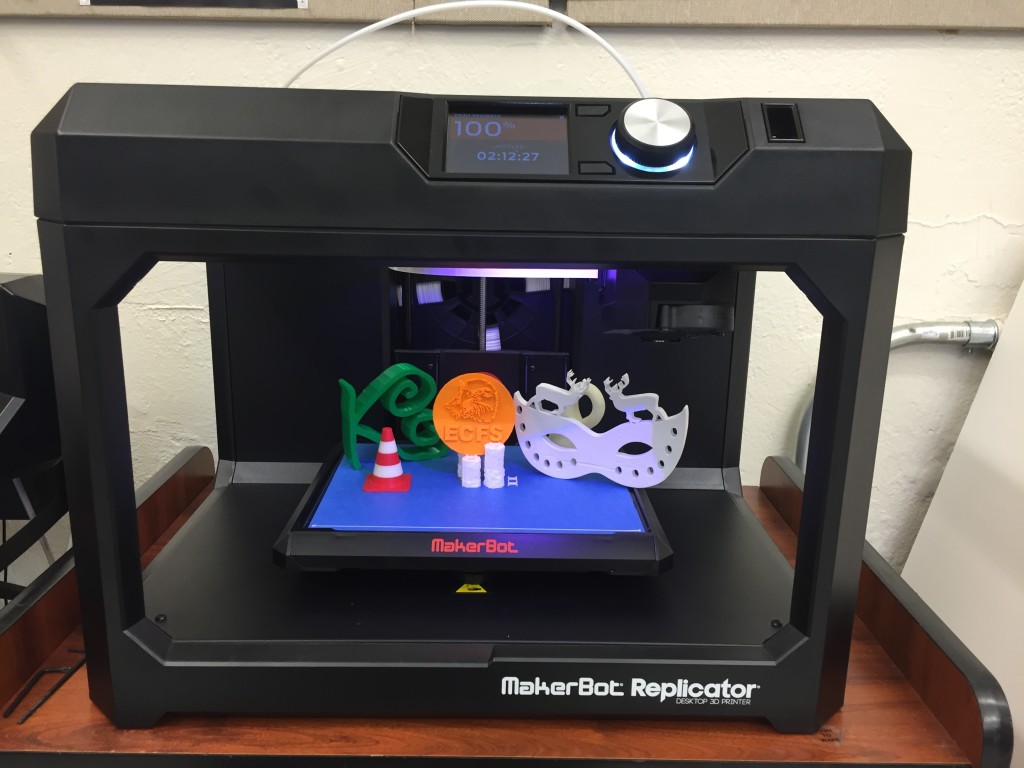

Using computer-aided design software, students can construct 3D models and then print them. When the 3D printer receives a model, it extrudes heated material onto a platform, building an object from scratch. Structures are printed using a variety of materials, including rubber, metal and most commonly, plastic.

Thomas Kalil, President Obama’s Deputy Director of Science and Technology Policy, says schools should start using 3D printers to inspire young engineers and solve problems hands-on.

“We wouldn’t teach football by lecturing to kids about football for 12 years before allowing them to play,” Kalil said. “That’s not the way we should engage in STEM (science, technology, engineering and math) education.”

Michael Hripko, another supporter of the fast-advancing technology, works for America Makes–an organization that helps classrooms across the United States obtain 3D printers.

“3D printing is a technology that enables students to make whatever they dream,” Hripko said. “Students print things like amateur rockets, components for drones and robotic parts. (3D printing) is an evolution of education; it’s going to become an integral component in high school education.”

There’s one hitch: 3D printers don’t come cheap (typically costing anywhere from $300-$15,000), so, as deputy director of workforce and educational outreach, Hripko teaches schools various techniques for raising money to purchase them. They include company sponsorship, parental contribution, budget reallocation and crowdfunding.

Responding to a call from Obama to encourage innovation, MakerBot, a New York-based 3D printing company, launched its Academy program in November — pledging to put a 3D printer in every school in the United States.

Six months later, MakerBot — which commands 20 percent of the 3D printing market, according to 3DHubs.com — has reached more than 400,000 students in 50 states.

“To compete at all,” said Academy director Ryan Luikens, “3D printing needs to be a requirement, the same way a computer lab was in previous generations.”

Another leading printing company, 3D Systems, founded its education program, M.Lab 21, in June.

“We envision M.Lab 21 as the 21st century shop class,” said Leanne Gluck, director of global social impact at 3D Systems. “The education market is really thriving. Everyone understands that 3D printing is the future.”

Since June, 200 schools across the country have expressed interest in M.Lab 21, and “two to three” more schools make inquiries about M.Lab 21 via email every day. Students use their printers in hackathons to design buildings and add flair to bicycles.

Todd Keruskin, an assistant superintendent in Pennsylvania, said 3D printers are a necessary new part of education.

“Designing things in a 3D world on a computer is really the world we’re heading to,” Keruskin said. “I want students to be able to think they can build and design anything. I want to reconnect them with creativity and innovation. I want to make sure my kids are prepared for the future.”

In his school district, which has 2,588 students, there are fourteen 3D printers which cost from $1,000 to $3,000 each. Keruskin’s students have used Google SketchUp on an iPad to design and print 3D candy bars and device holders.

Not everyone shares Keruskin’s enthusiasm for 3D printing.

“I think if you have a serious engineering program, it is a very valuable tool,” said James Dann, a science teacher at the Menlo School in Atherton, California. “But the way I see 99 percent of schools using it, it’s a waste of money. If you’re just going to print out balls and toys, what’s the point?”

At Fieldston, design teachers Carl Smith and Kirk Ruebenson both expressed a shared enthusiasm in the technology.

“Students are learning 3D visualization, they’re learning to draw their ideas like architects and they’re becoming designers,” Mr. Smith said.

After receiving a venture grant from the board in the spring of 2012, ECFS purchased its first 3D printer, a wooden MakerBot Replicator 1. Two years later, Fieldston has three total printers and a brand new 3D scanner in its Design Center.

Students, teachers and even the White House are jumping on the 3D printing bandwagon.

It is “a cultural phenomenon,” Kalil said. “There’s a growing interest in being a producer of things not just a consumer. The tools that are necessary to make things are more affordable and easier to use. But the real win will come with empowering the next generation to recognize that if they have an idea, they can use these powerful new tools to make it.”